Drug Enforcement Administration chief Chuck Rosenberg says the decision is rooted in science. Rosenberg gave “enormous weight” to conclusions by the Food and Drug Administration that marijuana has “no currently accepted medical use in treatment in the United States,” and by some measures, it remains highly vulnerable to abuse as the most commonly used illicit drug across the nation.

“This decision isn’t based on danger. This decision is based on whether marijuana, as determined by the FDA, is a safe and effective medicine,” he said, “and it’s not.”

Fuck that noise. The real reason for the rejection is it represents severely abrogating the power and majesty of too many government agencies at all levels.

Not only the DEA, but state and local cops depend on the Schedule 1 classification to help maintain the number of armed goons, their ability to seize your assets and excuses to roust you based on pure-T bullshit.

Not to mention all of the politicians who love to be “tough on drugs” and various “zero tolerance” policies.

Curtailing any of that simply cannot be tolerated. Because freedom is just too dangerous, you stupid, stupid proles.

I guess it is a sign of old age that my first Nigerian scam letter was a real letter, hand written, and delivered by the US Mail. It was when I had my shop in Fremont, CA. Since they had to pay postage I expect they were a little more selective and targeted me as a small businessman.

Dayum, Mac…I never heard of such things; I thought “419 scams” were only an internet phenomenon. Had no idea they tried them through the mail.

Jim teh Roofer’s company gets unsophisticated scam attempts every so often. The come-on is typically about “exclusive” leads to carp-tonnes of work on “select” high-buck homes; it’s usually just someone selling “ads”. But if they’re in the U.S., sometimes I’ll return the call just to screw with them. (I’m always amused at how indignant they get when they realize I’m yanking their chain.)

I think I kept it with old papers from the business. I will try to find it some day and scan it into my computer. It was interesting. I had never heard of such a thing and years later when I was into computers and saw reference to the “Nigerian scam” it gave me a laugh.

Sadly, a friend of mine that owned a tool supply store got caught up in something like a cross between this and what you describe. He thought he was going to get huge contracts (overseas, I think) and once they got him to put up money he just didn’t seem able to face that he was conned and they kept getting him to send more, millions in sales was just over the next hilltop. No one could convince him and it put him out of business. I had known him for years and had done some jobs he had contracted. I designed and made a pallet system for small machines and he sold a few sets. He took it to the big machine tool show in Chicago and had it mounted on a small CNC machine he was trying to sell as a vendor. It actually got some good attention from a company that was a big maker of larger pallet systems as it was smaller than theirs and was geared toward a niche market that might not justify developing their own line. If it had worked I would have been really set. Too bad.

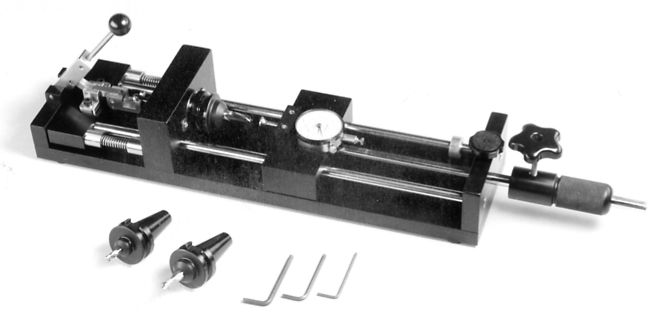

I also made this tool setter for the same manufacturer that ordered the pallet systems.

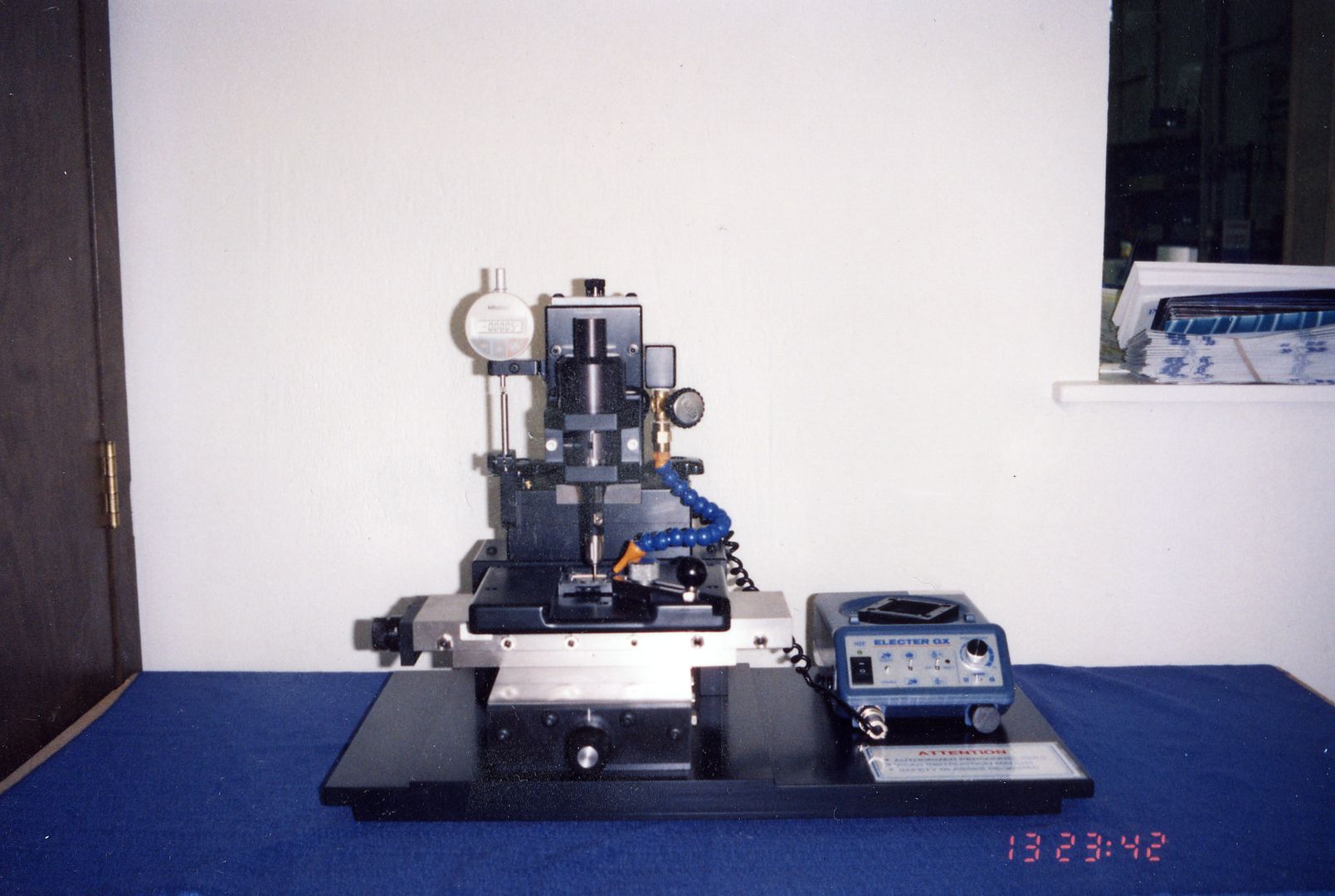

He also ordered this tool for Fujitsu. This was an interesting project.

That’s lousy that your friend with the tool supply store got conned.

Would’ve been nice if your pallet system had taken-off.

When I read the word “pallet”, I generally think of the splintery wooden sort used in shipping and warehousing…but I remembered there’s also a type used with CNC machines.

Learned that during a trip to a vendor’s shop when I worked for a musical instrument manufacturer many moons ago. Despite the fact I was involved in marketing / tech support, I learned a surprising amount about designing and manufacturing electronics. (The company encouraged employee’s curiosity about other areas of the operation, figuring -- correctly -- that good ideas might come from unlikely places.)

This was a small system, the pallets were 6″x6″ or 6″x8″ and the base was 6″x6″. I am not an engineer but liked to use toggle links in my designs. I over did it on my first design here with a toggle and camming surfaces, and the lockup felt spongy and vague. It had so much leverage it was flexing the 1/2″ tool steel plate that was the base of the pallet, even with two fingers on the operating lever. I redesigned it with less leverage and it locked up with a solid feel that made consistency easy. The pallets were 1″ or thicker aluminum but the pallet bases and the base units were all tool steel, nickle plated. The operating parts were hardened before plating. It was over engineered but it would hold .0002″ tolerances and repeatability consistently.

It was just much heavier and stronger than needed. If designed for larger scale production it could have been easier and cheaper to make but I designed it for me to produce on my equipment. The base unit was machined out of a 6″x6″x1″ piece of tool steel. It was the Tiger tank school of design.

Sure Happy It’s Thursday, Gerbil Nation!

Hai, Mac, Fatwa, Sven, and any lurking lurkers, lurking about.

Mac -- two tenths is nothing to shake a stick at, especially in a small package.

My trip home from beautiful downtown Burbank (sans Rowan and Martin) took about 2.5 hours (vs. 1.25 for the trip up). The first day of the training was both good and useful, and I got a chance to put faces with names and was even invited out to dinner with a bunch of the managers. The second day (today) was put on by a pair of consultants and was overly long and overly generalized. To top it off, by late morning I was feeling feverish and knew I had a good, solid cold. Oh, well, 1 out of 2 ain’t bad for most conferences.

Ha! First!

G’mornin’, GN!

Hai and congratters, Sven!

Mac --

Heh.

I got nothin’ else…’cept a bunch of carp to do; BBL.

DEA Rejects Attempt To Loosen Federal Restrictions On Marijuana:

Fuck that noise. The real reason for the rejection is it represents severely abrogating the power and majesty of too many government agencies at all levels.

Not only the DEA, but state and local cops depend on the Schedule 1 classification to help maintain the number of armed goons, their ability to seize your assets and excuses to roust you based on pure-T bullshit.

Not to mention all of the politicians who love to be “tough on drugs” and various “zero tolerance” policies.

Curtailing any of that simply cannot be tolerated. Because freedom is just too dangerous, you stupid, stupid proles.

Clever:

I guess it is a sign of old age that my first Nigerian scam letter was a real letter, hand written, and delivered by the US Mail. It was when I had my shop in Fremont, CA. Since they had to pay postage I expect they were a little more selective and targeted me as a small businessman.

Dayum, Mac…I never heard of such things; I thought “419 scams” were only an internet phenomenon. Had no idea they tried them through the mail.

Jim teh Roofer’s company gets unsophisticated scam attempts every so often. The come-on is typically about “exclusive” leads to carp-tonnes of work on “select” high-buck homes; it’s usually just someone selling “ads”. But if they’re in the U.S., sometimes I’ll return the call just to screw with them. (I’m always amused at how indignant they get when they realize I’m yanking their chain.)

I think I kept it with old papers from the business. I will try to find it some day and scan it into my computer. It was interesting. I had never heard of such a thing and years later when I was into computers and saw reference to the “Nigerian scam” it gave me a laugh.

Sadly, a friend of mine that owned a tool supply store got caught up in something like a cross between this and what you describe. He thought he was going to get huge contracts (overseas, I think) and once they got him to put up money he just didn’t seem able to face that he was conned and they kept getting him to send more, millions in sales was just over the next hilltop. No one could convince him and it put him out of business. I had known him for years and had done some jobs he had contracted. I designed and made a pallet system for small machines and he sold a few sets. He took it to the big machine tool show in Chicago and had it mounted on a small CNC machine he was trying to sell as a vendor. It actually got some good attention from a company that was a big maker of larger pallet systems as it was smaller than theirs and was geared toward a niche market that might not justify developing their own line. If it had worked I would have been really set. Too bad.

I also made this tool setter for the same manufacturer that ordered the pallet systems.

He also ordered this tool for Fujitsu. This was an interesting project.

That’s lousy that your friend with the tool supply store got conned.

Would’ve been nice if your pallet system had taken-off.

When I read the word “pallet”, I generally think of the splintery wooden sort used in shipping and warehousing…but I remembered there’s also a type used with CNC machines.

Learned that during a trip to a vendor’s shop when I worked for a musical instrument manufacturer many moons ago. Despite the fact I was involved in marketing / tech support, I learned a surprising amount about designing and manufacturing electronics. (The company encouraged employee’s curiosity about other areas of the operation, figuring -- correctly -- that good ideas might come from unlikely places.)

This was a small system, the pallets were 6″x6″ or 6″x8″ and the base was 6″x6″. I am not an engineer but liked to use toggle links in my designs. I over did it on my first design here with a toggle and camming surfaces, and the lockup felt spongy and vague. It had so much leverage it was flexing the 1/2″ tool steel plate that was the base of the pallet, even with two fingers on the operating lever. I redesigned it with less leverage and it locked up with a solid feel that made consistency easy. The pallets were 1″ or thicker aluminum but the pallet bases and the base units were all tool steel, nickle plated. The operating parts were hardened before plating. It was over engineered but it would hold .0002″ tolerances and repeatability consistently.

I am in awe.

I’m not conversant with machining, but that doesn’t seem over-engineered; seems more like “dependable”.

It was just much heavier and stronger than needed. If designed for larger scale production it could have been easier and cheaper to make but I designed it for me to produce on my equipment. The base unit was machined out of a 6″x6″x1″ piece of tool steel. It was the Tiger tank school of design.

Sure Happy It’s Thursday, Gerbil Nation!

Hai, Mac, Fatwa, Sven, and any lurking lurkers, lurking about.

Mac -- two tenths is nothing to shake a stick at, especially in a small package.

My trip home from beautiful downtown Burbank (sans Rowan and Martin) took about 2.5 hours (vs. 1.25 for the trip up). The first day of the training was both good and useful, and I got a chance to put faces with names and was even invited out to dinner with a bunch of the managers. The second day (today) was put on by a pair of consultants and was overly long and overly generalized. To top it off, by late morning I was feeling feverish and knew I had a good, solid cold. Oh, well, 1 out of 2 ain’t bad for most conferences.